End to End Plastics Solutions

At Vidhata we Make Moulds as well as Moulded Plastic Parts

Welcome to Vidhata. We offer a comprehensive range of plastic manufacturing solutions designed to meet the unique needs of various industries. With our state-of-the-art facilities and expert team, we deliver high-quality products and exceptional service.

Product Design and Prototyping

We excel in transforming your innovative ideas into tangible products. Our product design and prototyping services are tailored to ensure your vision is realized with precision and efficiency.

Concept Development: Collaborate with our experienced designers to develop your concept. We work closely with you to understand your ideas and requirements, transforming them into detailed project plans.

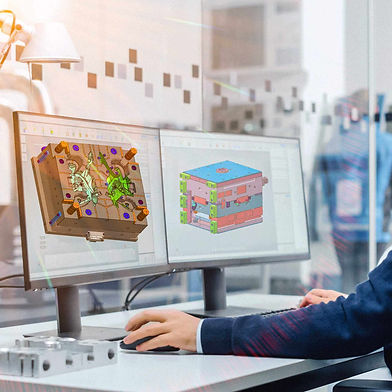

CAD Modeling: Utilize advanced CAD software for detailed and accurate design. Our CAD modeling services ensure that your product designs are precise, functional, and ready for the next stage of development.

Rapid Prototyping: Create functional prototypes quickly to test and refine your product. Our rapid prototyping capabilities allow you to evaluate the design, make necessary adjustments, and move forward with confidence.

Benefits:

-

Accelerate time-to-market: Reduce development cycles and bring your products to market faster.

-

Validate design concepts: Test and refine your ideas before full-scale production.

-

Minimize development risks: Identify and address potential issues early in the process.

Tool and Mouldmaking

Our in-house toolroom is equipped with the latest machinery to create high-precision molds and tools. This integrated approach guarantees smooth transitions from design to production, ensuring your products meet the highest standards of quality and efficiency.

Tool Design: Custom tool designs to fit your specific requirements. Our experienced team ensures that every tool is designed to optimize production efficiency and product quality.

Mould Manufacturing: High-quality molds using advanced CNC machinery. We use state-of-the-art equipment to manufacture molds that are durable, precise, and capable of producing consistent, high-quality parts.

Maintenance and Repair: Regular maintenance and prompt repair services to keep your tools in top condition. Our proactive approach ensures that your production line runs smoothly without interruptions.

Benefits:

-

Enhanced product quality: High-precision molds result in superior finished products.

-

Reduced production time: Efficient tool and mold design minimizes production delays.

-

Cost-effective solutions: Reliable molds reduce the need for frequent replacements and repairs.

Injection Moulding and Parts

We offer advanced injection moulding services, producing top-notch plastic components for a variety of applications. Our expertise in working with different thermoplastics ensures precise and reliable results.

Materials: We work with a wide range of materials including PP, HDPE, PC, ABS, Nylon, and more. Our extensive material knowledge ensures that we select the best options for your specific needs.

Techniques: Utilization of the latest injection moulding technology for consistent quality. We employ cutting-edge machinery and techniques to ensure each component meets your exact specifications.

Scalability: Capable of handling both low and high-volume production runs. Whether you need a small batch or large-scale production, we have the capacity to meet your demands.

Benefits:

-

Consistent product quality: Advanced techniques ensure uniformity across all components.

-

Competitive pricing: Efficient processes and economies of scale allow us to offer competitive rates.

-

On-time delivery: Our streamlined operations ensure timely production and delivery of your orders.

Polyurethane (PU) Products

We specialize in the manufacture of high-quality Polyurethane (PU) products, catering to a variety of applications across multiple industries. Our expertise in PU production ensures durable, reliable, and efficient results.

Materials: We produce a diverse range of PU products, including PU moulded components for Defence, sporting goods, cricket team kits, and various industrial sectors. Our extensive material knowledge allows us to select the best PU formulations for your specific needs.

Techniques: Utilizing state-of-the-art PU production technology, we ensure consistent quality. Our advanced machinery and techniques guarantee that each product meets your exact specifications, providing exceptional performance and durability.

Scalability: Capable of handling both low and high-volume production runs, we meet your demands whether you need a small batch or large-scale production. Our facilities are designed to scale efficiently to accommodate your needs.

Benefits:

-

Versatile Applications: Our PU products serve a wide range of industries, from Defence to sports, ensuring you get tailored solutions for your specific applications.

-

High Durability: PU products are known for their strength and longevity, making them ideal for demanding environments.

-

Innovative Solutions: Our expertise and cutting-edge technology enable us to provide innovative and effective PU solutions.

-

What types of plastics do you work with?We specialize in working with a diverse range of thermoplastics, including materials like Polypropylene (PP), High-Density Polyethylene (HDPE), Polycarbonate (PC), Acrylonitrile Butadiene Styrene (ABS), Nylon, and Polyurethane (PU), among others. Our extensive expertise in these materials enables us to select the most suitable option for your specific application, ensuring that your products achieve the highest levels of durability, performance, and quality. Whether you're looking for strength, flexibility, or resistance to environmental factors, we tailor our material choices to meet the unique demands of your project.

-

Can you assist with the design and prototyping of custom products?Absolutely! Our team specializes in turning your ideas into reality. We offer comprehensive design and rapid prototyping services, using advanced CAD software to create precise models and prototypes tailored to your needs.

-

What industries do you serve?We serve diverse industries including pharmaceutical, engineering, automotive, electronics, medical, and consumer goods. Our versatile capabilities allow us to meet the unique requirements of each sector, delivering high-quality plastic solutions.